- IMS Implemented

- SAP Integrated

- ATEX Certified

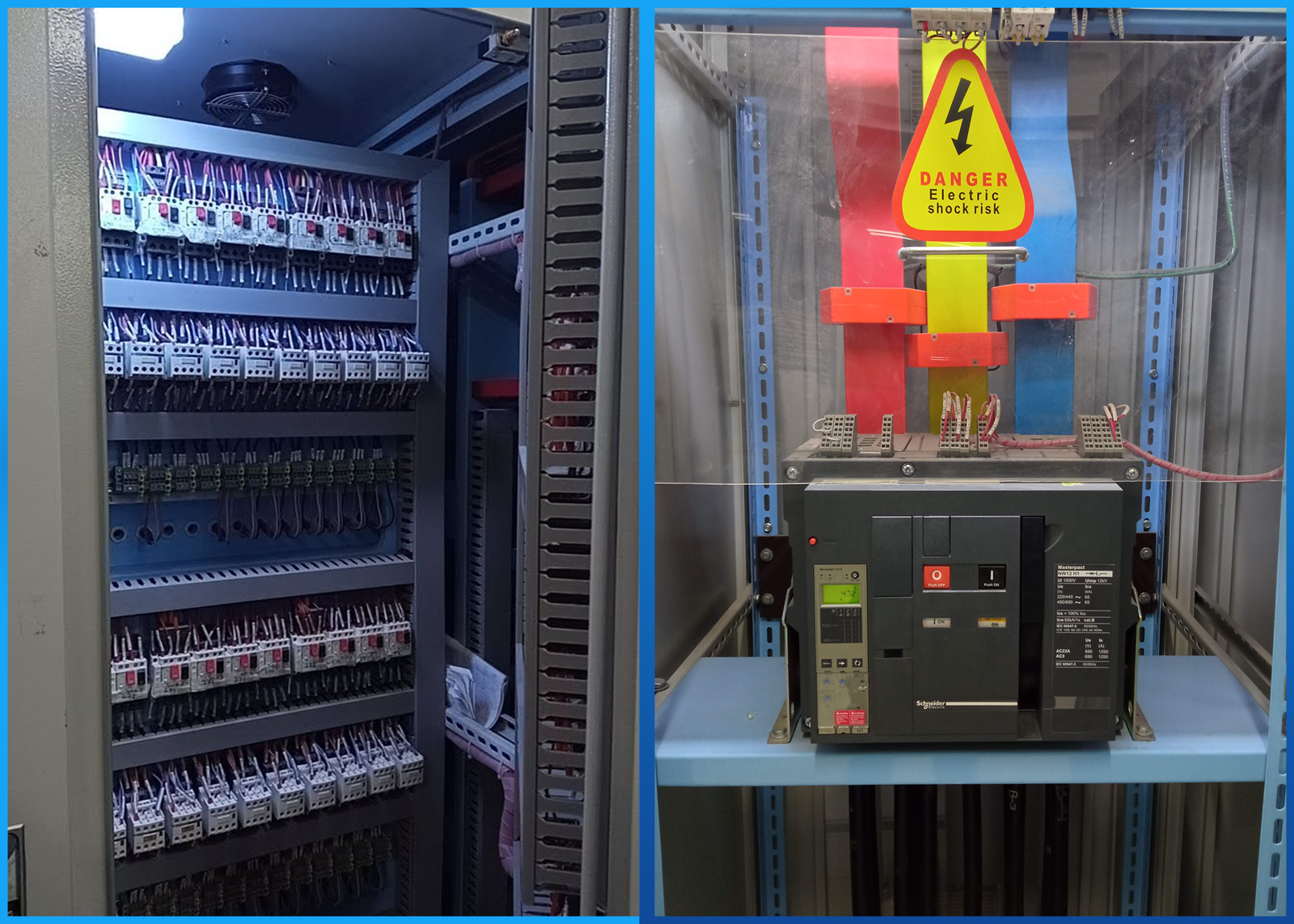

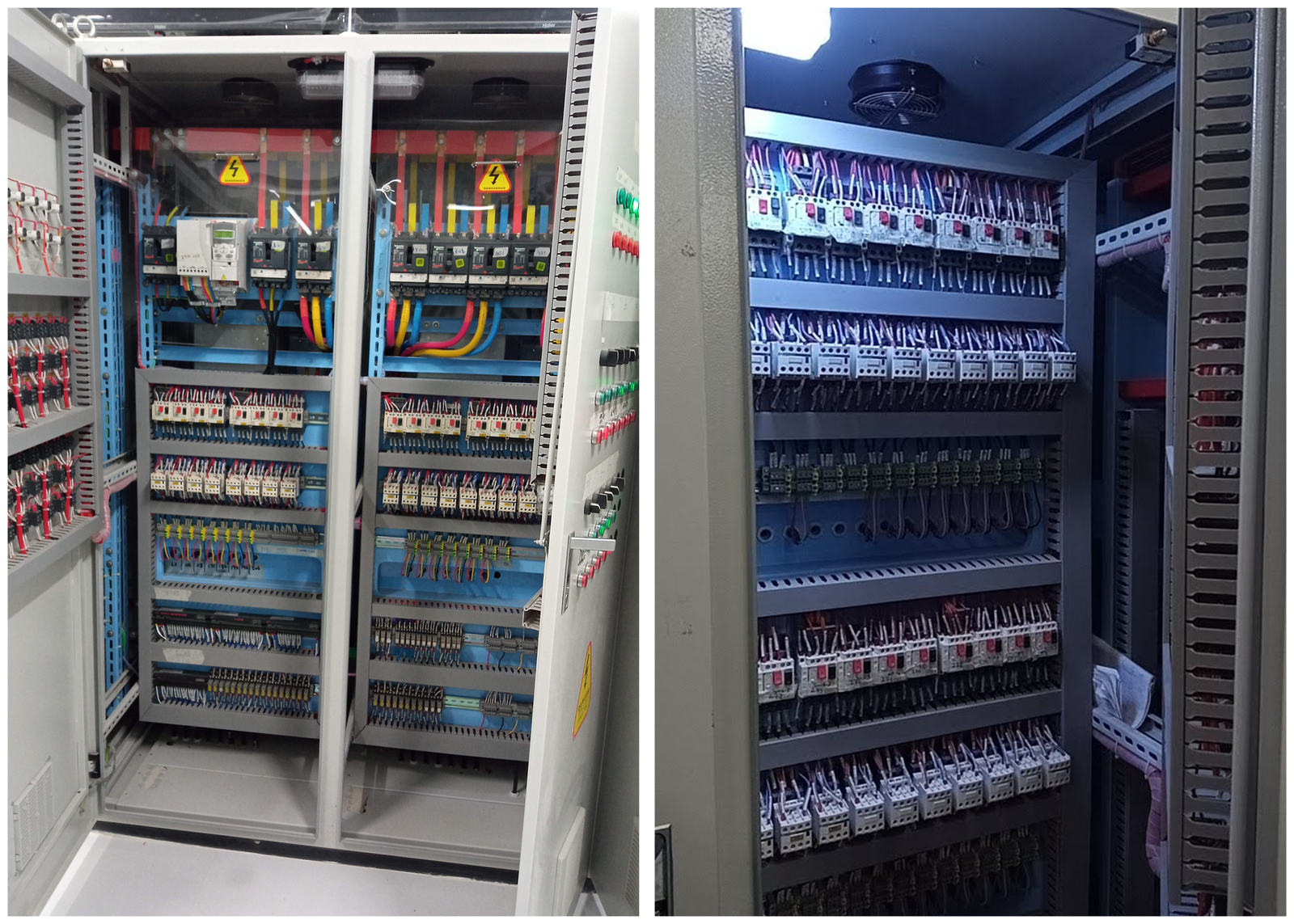

LT Protection Panels

Customized 440V Low Voltage Protection Panels as per the customer’s Load Schedule or Single line drawing (SLD).

Marketing, Design & Proposal (Experienced & Seasoned Team):

Our experienced and seasoned team of marketing, design, and proposal engineers play a crucial role in understanding customer requirements and translating them into technical and commercial documents. We openly discuss all options with the customer and design a cost-effective system that adheres to IEC standards and good engineering practices.

Mechanical Fabrication (Ensuring Absolute Accuracy):

We utilize advanced and automated laser cutting machinery for our fabrication works. This significantly impacts the final outlook of the cubicle, improving aesthetics by eliminating manual cutting flaws and inaccuracies.

Enclosure/Structure (Extra Durability & Longevity):

Our manufactured enclosures are constructed using 14-gauge MS Sheets. These sheets are treated with high-quality chemicals, acids, and zinc phosphate before being powder coated, resulting in enhanced mechanical strength and attractive aesthetics for your Substation. To ensure quality control and assurance, we meticulously check the micron thickness at every coat through our qualified engineers and testing equipment.

Equipment/Components (Genuine Breakers, Wiring & Busbars):

We exclusively select licensed and authorized distributors for procuring breakers, wiring, busbars, and other components required for our LV Switchgear. Each component undergoes thorough testing by our qualified engineers and testing equipment to ensure quality control and assurance.

Testing (SAT & FAT):

We encourage our customers to join us and observe the final stage of their product’s completion, known as the Factory Acceptance Test (FAT). During the FAT, our qualified engineers and testing equipment sequentially test the product to ensure its satisfaction to the customer.

Additionally, we offer Site Acceptance Test (SAT) services to integrate our product into the customer’s existing facility on-site. Our installation team conducts the SAT during the commissioning and handover stage. This test re-verifies all the parameters that were previously complied with during FAT in the presence of the customer. Once the SAT is successfully completed, the product is handed over for long-term usage.

Warranty & Claims:

We provide our customers with a standard one-year back-to-back warranty for all equipment and panel performance. Although our products are manufactured to perfection, external circumstances can sometimes impact individual components. Our aftersales team is dedicated to promptly addressing and resolving any customer claims that may arise.